|

Equipment Brochure

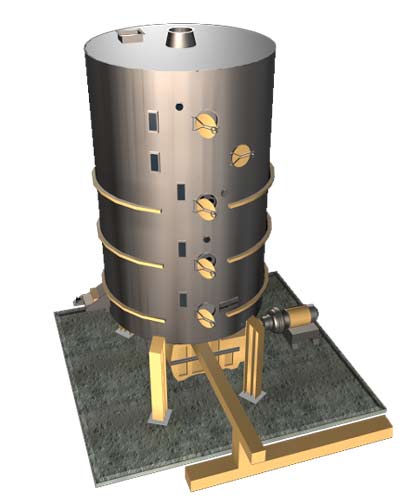

The Design

The Crown/Schumacher design (Schumacher being the German inventor of the original unit of which Crown became the sole American licensee) has been modified and improved continuously to meet market needs especially the industry demand for increased tonnage per unit.

The result has been dominant market acceptance so that today the number of Crown Schumacher units built offering this most modern technology is over 240.

Points to Remember

- Unequalled experience with DT's, DC's and DTDC's with more references worldwide than all the competition combined.

- Capacities available from 1 to 7000 tonnes per today

- 30 5.6m dia (220") units installed in the last few years meeting the demand for larger units. It is estimated that 7 Crown units handle 10% of the worlds soybean meal.

- Efficient, robust, reliable and simple to operate.

- Intimate contact and counter-current flow of sparge steam, combined with special hollow stay bolt design provides low steam usage and minimum PPM hexane in meal.

Advantages of the Crown/Schumacher DTDC

- Significantly lower steam usage and distinctly lower solvent losses due to unique, counter- current flow.

- More stable meal temperatures in all lower trays allow a greater degree of safety. A drop in meal temperature in the top tray due to operation errors can also be recovered more easily in the second or succeeding trays.

- Automatic level control through chutes and variable rotary valves means less operator attention.

- Low horsepower per ton requirements.

- Uses same heavy duty steam chests, and sweeps that have been proven over the years in conventional Crown DT’s and DTDC’s. Sweep arm breakage and bending is almost unheard of.

- DTDC’s capital costs and space requirements are less than separate DT’s and DC’s.

- The “predesolventizing” by the steam-heated trays reduces the amount of sparge steam required, and also reduces the meal moisture proportionally, thereby reducing the steam usage in the meal dryer.

- Predesolventizing trays are basket type. Vapours flow around trays with low velocity. Fewer fines carried by vapours.

Desolventiser Toaster

After the oil has been removed from the flakes or cake, they leave the Crown Extractor with approximately 30% solvent (hexane) content. The Crown/Schumacher DT is the newest innovation in removing the hexane from the flakes and completing the toasting operation.

The solvent laden flakes enter the top and land on the predesolventizing tray, which is steam heated. The flakes are evenly distributed onto the first main tray.

Each main tray has hollow stay bolts for venting vapours from one tray to the next. The quantity and position are carefully designed to allow maximum contact between vapours and meal.

Steam is injected through the perforated bottom tray. The steam strips the final solvent from the meal and then vents up through all the trays above. A true counter current desolventization is achieved, previously unavailable in DT’s. The result is a uniquely low solvent content in desolventised meal, and significantly reduced solvent losses.

The meal flows from one tray to the next through chutes. The bottom tray contains a specially designed variable speed rotary valve to maintain a level.

The combination of the steam heated trays and counter-current steam stripping raises the meal temperatures faster and slightly higher than conventional DT’s. Temperatures are more stable in lower trays and provide for a greater degree of safety

Dryer-Cooler

The Dryer-Cooler, when used with the Desolventizer-Toaster, will dry and cool almost any solvent extracted vegetable oil bearing meal. The drying and cooling is accomplished by injecting heated air in the drying section and using ambient temperature air to cool the meal in the cooling section. The evenly distributed flow of hot air and cool air in a true counter-current system results in extremely high efficiency and reduces energy costs. This produces a meal with the desired characteristics for sale and storage.

The Dryer/Cooler unit works equally well combined with a DT or used as a separate unit, depending upon customer preference.

Click here for DTDC equipment brochure. |