System designed for processors who have existing preparation equipment and need to add dehulling.

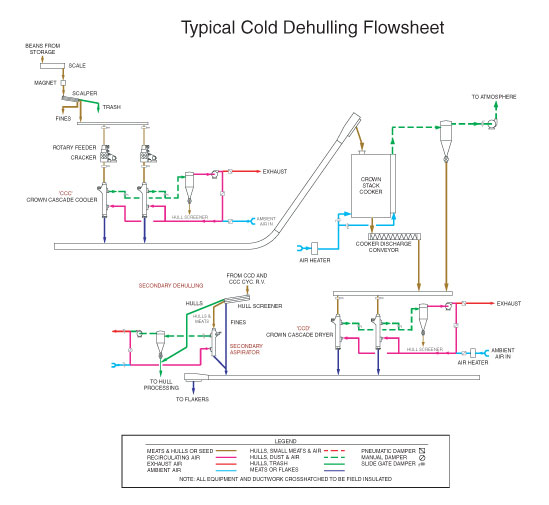

PROCESS DESCRIPTION:

The Crown Cold Dehulling process is used when the customer has a grain dryer or conditioners already installed and they simply want to add aspiration to their system to create a high protein meal. The cold dehulling system will have the Crown Cascade Dryer ‘CCD’ after the cracking rolls. In the CCD, the beans and hulls cascade downward releasing hulls from the meats. Re-circulated countercurrent heated air will lift the hulls separating the two products. After the CCD, the meats enter either an existing rotary conditioner or stack cooker for future conditioning. In this conditioner, additional hulls are released from the meats. This material is sent to the Crown Cascade Cooler ‘CCC’. As in the CCD, the meats cascade downward, releasing the last remaining hulls. The heavier meats fall out the bottom of the CCC as the lighter material is lifted with the countercurrent airflow. In the CCC, warm air is again introduced to maintain proper extraction temperatures. The product lifted in the CCD and CCC is a combination of hulls and small meats that are separated in the Crown Secondary System. A two deck Hull Screener is used to size the material in three cuts, hulls sent to hull processing, meats sent to flakers, and the middle cut, a combination of small meats and hulls. The middle cut is sent to a Crown Secondary Aspirator where the final fiber and hull fat separation is controlled.

|